Well the aft decking is and this is taking some time the main struggle of the weekend was to remove the SS screws from the track risers on each side of the hull, the first one came after a struggle so I do have a template to recreate from but the 2nd I admitted defeat with there were.

Buried screws and screws the went through the riser, the deck and almost through the inch inner frame most of these came in pairs and they just would not turn in the attempt that the glue would fail under pressure and the deck might part from the inner frame the heads were drilled off this did not help so it was destroy the riser to remove the screws with a pipe wrench.

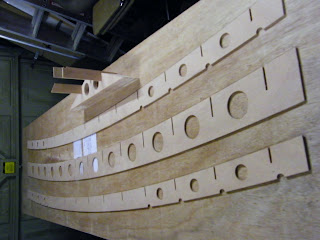

Most of the stringers the glue has failed on so it is out with those that have failed and clean the joints off ready to epoxy them back in place the ply that was lifted off came out at 4.5mm so taking into account the ply had been treated on both sides on more on the top than the bottom I would say it was 4mm or its imperial equivalent.